Hampshire County Council

Cavity Wall Insulation

INTRODUCTION

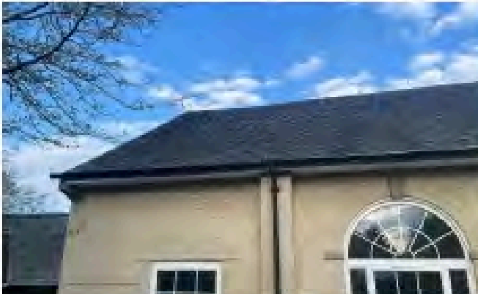

Hampshire County Council received funding through the Public Sector Decarbonisation Scheme (PSDS) to improve energy efficiency across 28 independent schools. TF Energy successfully completed cavity wall insulation works with a project cost of £600,000, finishing in March 2023. The project aimed to minimise heat loss, lower energy consumption, and support government "Net Zero" goals while navigating the challenges of working in live school environments with vulnerable children.